Flooring is key to health and safety compliance for the food and beverage sector

There’s no downturn, slowdown or uncertainty in the UK food and beverage sector. Recent figures by Persistence Market Research suggest that the food and beverage sector will grow by a staggering 5% to 2024. That growth hasn’t gone unnoticed. Regulatory bodies in the UK, EU and US have responded with even stricter health and safety standards that leave food and beverage companies increasingly accountable for outbreaks of contaminants, pathogens and harmful bacteria.

The shift towards large scale factory production in the UK in order to meet demand makes it too easy for contaminants to enter the supply chain, workers to injure themselves, and operating costs to spiral. Leading organisations in the UK Food & Beverage sector have taken the initiative. Producers such as Danone and Pepsico have discovered how innovative industrial flooring solutions can assist with their food safety regime, and allow them to focus on business growth.

The UK Food & Beverage sector faces these challenges

CONTAMINATION OUTBREAKS

Secure the floor area in a food and beverage production environment and you can nip contamination in the bud in most cases. Gravity attracts most contaminants, and the floor area becomes a nurturing ground for microbes and bacteria, especially where there are above average levels of moisture.

The solution is a flooring system that is seamless and impervious to germs, moisture and chemicals, not just on the surface but in the cracks and gaps too. This should also extend to the edge of the floor, where it meets the wall, by using coving to ensure a smooth and consistent transition from flooring to wall. Coving also makes the wash down process faster and more effective, by containing the water and making corners and sides easier to access.

UK foodservice operations have discovered that resin floors are the most effective solution, with PMMA resin flooring, in particular, proving itself as a match for any bacteria. Its seamless, monolithic surface is covered with a non-porous resin screed, which is easy to clean, totally impervious to germs and is 98% cleaner than standard PU floors.

Danone Nutricia are producers of infant milk formula, a sector that demands the very highest levels of hygiene and one that has experienced substantial growth in recent years. As the base powder forms part of all Danone baby-nutrition formula products, maintaining a safe and sterile environment was all-important. Danone chose PMMA resin flooring throughout their various production and packaging facilities across Ireland, due to its unrivalled hygienic properties.

“We have laid over 20K square meters of PMMA flooring over the past 5 years. We find the product excellent for hygiene, ease of application & durability together at a reasonable cost.”

Donal Dennehy, Ind Director IRL, Nutricia Infant Nutrition Ltd

“After carrying out a number of trials to determine what we believed to be the best flooring product for our milk powder processing plant areas we selected Floortech’s Trazcon® PMMA floors. The building finishes within our powder plant must satisfy stringent audits from our customers and other regulatory bodies,

and high-quality clean floors are key to this. The finish to the floors must be such that particles, spillages etc. are easily cleanable”.

Michael Collins, Project Engineer, Dairygold Ireland

WORK SAFETY

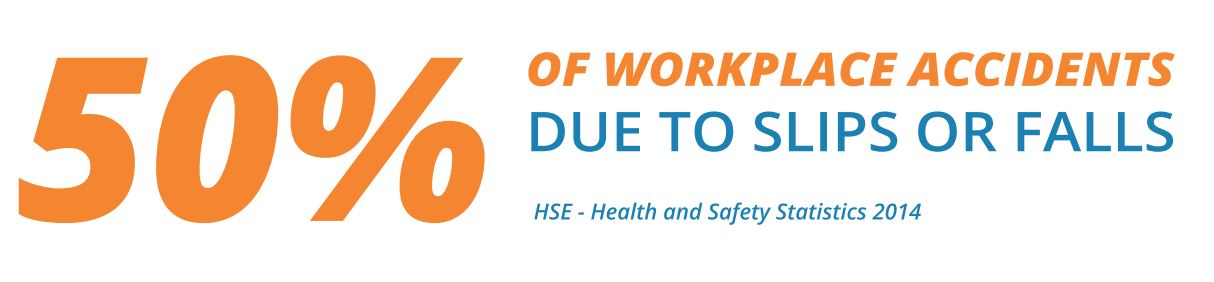

Almost half of all serious accidents in the workplace are due to slips and falls. According to the European Union’s statistics office Eurostat, the number of fatal accidents in the workplace is also on the rise in an alarming 17 of the 28 member states. Consequently, food and beverage operators need to design slip resistance into their flooring solution to eliminate risk and liability.

What is the key safety challenge for the sector? Quite simply, a food service floor is inevitably a wet or slick surface. A textured surface will enhance grip, but this might come at the expense of hygiene since ridged, bobbled or distressed surfaces harbour bacteria more readily.

Fortunately, Floortech®, offers PMMA resin flooring certified to the highest standards of both Food Conformity (EN1186) for hygiene, and Slip Resistance (BS7976-2:2002), allowing Food & Beverage facilities to ensure impeccable hygiene standards and keep workplace accidents to a minimum. Anti-skid coatings can also be reapplied quickly and with ease, so facilities never have to compromise on safety or experience periods of downtime.

CASE STUDY

The meat production industry subjects flooring to incredibly stressful conditions. This is why Liffey Meats, one of Ireland’s leading beef processors, chose a FloorTech Trazcon® PMMA flooring system, when they upgraded their 600m2 boning hall in Cavan.

They needed a solution that was extremely durable and hygienic, which also offered excellent anti-slip qualities. The solution they chose not only conformed to the highest standards in all these areas, but the entire 600m2 floor was also installed over one weekend, with production commencing again on Monday, meaning business disruption was kept to an absolute minimum.

COSTS ARE ON THE RISE

The longevity of a typical UK Food & Beverage facility is under constant threat from heavy machinery, rigorous cleaning, chemical spills and high footfall. These all contribute to the wear and tear on the flooring surface. When choosing an industrial flooring solution, it is important for owners to factor in the cost of maintenance, repair and replacement to give the Total Cost of Ownership.

As a guideline, standard PU and Epoxy flooring need to be replaced entirely every 10 years. Neither is suitable for ongoing, incremental repairs. By contrast, PMMA resin flooring can be upgraded or repaired without having to remove the existing floor, dramatically increasing its longevity, with floors generally lasting 30 years or more. After repair, the flooring hardens to form a completely seamless surface once more, which can withstand heavy vehicle and foot traffic without lifting, cracking, fading or wearing.

CASE STUDY: Pepsico

The PMMA flooring systems Pepsico installed over 20 years ago are still performing as well today as the day they were first laid. They continue to exceed all health & safety requirements particularly from a slip-resistance and ease of cleaning perspective.

LAYING THE FOUNDATION FOR FOOD SAFETY

Before considering the best flooring for Food & Beverage production facilities, you should first determine all use requirements – both current and future. For extreme durability, increased hygiene standards, anti-slip properties or just the ability to repair and upgrade their flooring easily, PMMA resin flooring has proven to deliver the best results.

To learn more about resin flooring and PMMA resin flooring, contact our team today on +44 16 1775 2942 (UK).

Request a Quote

Please provide as much detail as possible about your specific needs & a member of our UK team will be in touch.

We do not install domestic flooring.